At Component 2.0, we turn ideas into motion.

We blend sharp engineering with curiosity and hands-on experience, pushing mechanical challenges into real, working solutions.

Powered by physics and a drive for progress, we create results that add clarity, pace, and real-world impact.

We create value through:

- Portfolio architecture and technical turnarounds

- Mechanical solutions for mass-produced products

- Mechanical solutions for mass production lines

- Mechanical solutions for test and measurement equipment

- Mechanical testing

- Mechanical IP protection

6+ years >731 components 25 employees >30% improvement -173 tons CO2 per year

Over the past 6+ years, our work has reached the market in 731 components, thanks to the efforts of our 25 employees. Component and/or system performance lifts by at least 30%. We've reduced our customers' carbon footprint by over 173 tons of CO₂ per year.

We get there with Everypoint Design: treating every infinitesimally small surface and volume as a variable to be optimised. We do so fast and within your constraints. In-house tools and experience accelerate the search. Sometimes it's a 1-hour review, sometimes a 5-year program. What is essential is that the results get live in your market.

Everypoint Design build on tools like:

Design reviews, failure analysis, product development, simulation, tolerance, robustness engineering, DFM/DFA, Prototyping and test rigs, Automation tooling and purpose-built jigs, Second-opinion assessments, Sustainability-driven weight/cost reductions, and many more

Fields of expertise

The same mechanical principles, optimisations, and tools apply widely. We’re not limited by industry - we do mechanics.

We’ve delivered solutions to various industries, including medical devices, energy, automation & machinery, consumer electronics, and injection moulding, and we’re equally at home elsewhere.

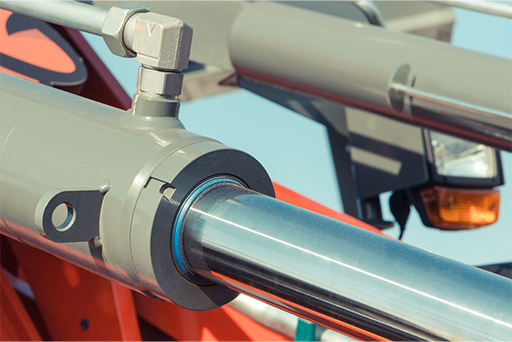

Components

Across industry we see the same issues recur, so we’ve developed machine components that systematically address them. Many originate in over-constrained designs that leave no allowance for manufacturing variation, assembly, wear, or thermal movement. Rather than redesigning a proven machine, our components selectively relieve constraints, eliminate parasitic loads, and reduce tolerance sensitivity.